The features of Matrixmetal

Characteristics:

Automation from A to Z with ona package

Matrixmetal is a total solution for the automation of all disciplines at steel construction companies. Matrixmetal provides solutions for every department. From quotation calculations and project planning to delivery and invoicing.

CRM - Customer Relationship Management

Manage all corporate customers, private customers and suppliers. Provided with a contact registration for recording all correspondence, including documents. All information centrally registered and easy to consult.

Quotations

All articles and prices from suppliers in libraries. Easy input or import of a BIM model. Fast calculation of all materials, articles, hours and prices. Forms the basis for a competitive and representative offer.

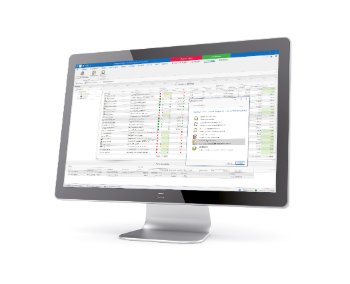

Offer and order management

Through the offer management, the Sales department keeps a grip on all requests, quotations and orders. Successful business starts with a streamlined sale.

Project management

Managing all current projects: From request and quotation to production and delivery. Insight into the status and progress of all current projects on one overview screen. Maximum grip on projects.

Project planning

Planned all current projects over time. Direct insight into the capacity and capacity utilization of each department. A powerful tool for coordinating planning between the customer and internal production.

BIM - Building Information Model

Digital exchange of steel construction models. Use a designer's model as the basis for the production model. And share the final production model with clients or construction companies.

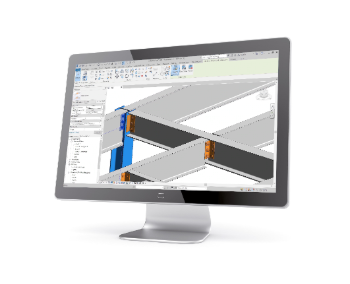

Engineering

Model and detail steel structures with Autodesk Advance Steel. As soon as the drawings and parts lists are approved and final, purchase the material and prepare the data for the machine control for production.

Purchase management

Ordering materials and articles from suppliers. Reservation and recall of materials from stock. EDI digital messaging for smooth, fast and error-free orders. Digital processing of goods receipt and delivery notes.

Stock management

Managing the stock items that are not ordered and delivered on a project basis. Insight into all stock positions and all stock reservations. Articles available on time and no unnecessary and expensive stock positions.

CNC - Computer Numeric Control

Control of machine tools based on DSTV, NC, DXF and STEP, such as saw-drill machines, punch-cutting machines and plasma cutters. For fast and efficient control of production.

Time registration

Registration of hours worked using barcodes, tags, tablets or smartphones. Also registration of presence and absence. The registration forms the basis for analyzes of the presence and occupancy of departments and people and for subsequent calculation.

Mobile devices

Information about relations, projects and time registration is available via tablets, smartphones and internet browsers. Production data such as drawings, materials and work instructions are also available for mobile use in the workshop. Step by step towards a paperless factory.

Deliveries

Manage all deliveries of steel structures. Reserve, organize and plan loads. And taking care of the correct waybills, including packing slips, CE documents and labels.

CE marking

Registration and administration of all CE markings for steel structures. Provides options for all required waybills and labels. Also provided with options for management reporting.

Purchase and sales invoices

Draw up and send sales invoices immediately after or upon delivery. To be drawn up per partial delivery or per term. Automatic digital transmission and exchange of invoice data for invoice entries in financial software, including Exact, Accountview and Multivers.

Management analysis

Analysis of realized man hours and consumed materials in relation to the quotation calculation and the project budget. Through the Time Registration you have all the man hours realized. Via Purchasing and Stock, insight into all materials used. Together they form valuable management information.

Document management

Central storage of all documents from customers, suppliers and internal employees. Suitable for all types of files. To be classified by task or department, such as among relations, under projects or under purchase orders. All documents always and immediately at hand.

Let us advise you

The design of steel structures is a specialty and requires expert consultants.

For this reason we would like to advise you about all options of MatrixMetal for production of steel structures.

Call us or respond via the website for contact with one of our consultants. Would you like to discover the software yourself?

Ask for a demo version.