Matrix Software is a great party that is open to development

Jan Sytze van der Velde

technical director Europroyl

Extensive automation

In 2018, Europrovyl opened the Netherlands' largest and most modern plastic window frame factory. While the office is fully equipped for the New Way of Working, the 8,150 m² large production hall contains the most advanced machinery for plastic window production in the most optimal routing. "Both the machines and their controls are highly automated," says Van der Velde. "The complete pre-processing – sawing and milling of profiles, for example, takes place in one processing centre, after which the products are forwarded to our fully automatic welding department. And the pre-assembly and fittings are also largely done with robots."

|

|

|

Equal platforms, equal systems

Europrovyl has been using Matrix OptiCalc for approximately seven years for production, calculation, and work preparation. The choice for this software from Matrix Software is a logical one, according to Van der Velde. “Our sister companies Kumij and Transcarbo already used Matrix Software, and our ambition is that all companies within our group work on the same platforms and with the same systems. This means we only have to enter our data once. Moreover, we can invest together in optimisations, and developments will go faster. To select the right software for this, we actively exchange best practices. Matrix Software stands head and shoulders above this. The product managers and software engineers actively think along with us. They understand our products and can quickly translate what our machines need into the best software solution. Moreover, the software is suitable for calculation, work preparation and machine control, which saves time and costs.”

Calculation and work preparation

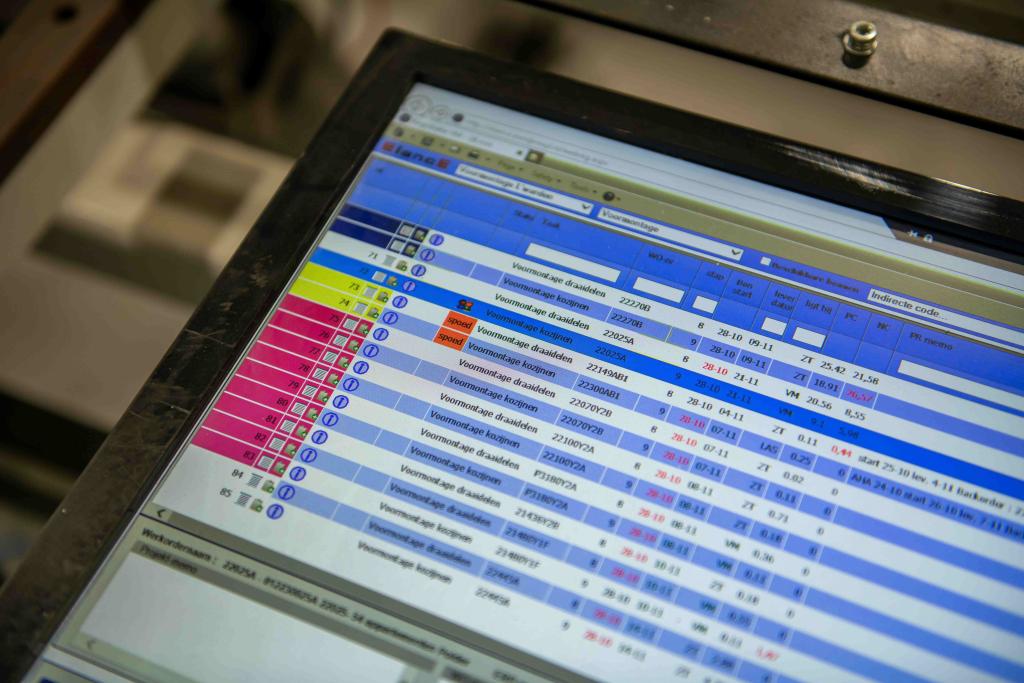

“We carry out the complete calculation of our frames in Matrix OptiCalc,” says Van der Velde. “In most cases, we receive drawings or BIM models from the contractor, which we read into Matrix OptiCalc. We then design and model the frames, after which a price and quotation are automatically generated based on, among other things, numbers, materials, person-hours and prices. After approval, a transfer takes place to our work preparation, which, for example, coordinates measuring on-site and enters all dimensions. We can then easily retrieve the material lists, order forms and other information from the software. The information is also shared with our ERP system. For the MRP part, we use third-party software packages, which take care of the further translation.”

Machine control

The machine control is done 100% from Matrix OptiCalc. “For this purpose, the software generates an XML file from the 3D models, which is automatically read by our machines,” says Van der Velde. “This means that exactly those products are produced that we came up with at the front.” In addition, Europrovyl has been using the online calculation tool WebKozijn for some time now. “We mainly make this tool available to dealers, who can easily make their frame drawings online and generate quotations.” The significant advantage of WebKozijn is that Europrovyl can determine the storage percentage and sales offer strictly for each dealer. “As a result, we offer customization to every dealer and keep a grip on window frame sales. We can make any frame that our dealers design in WebKozijn.”

Open for development

“Matrix Software is a great party that is open to development,” emphasizes Van der Velde. “Of course, the product managers and software engineers cannot come up with everything themselves, but if you come up with a good story, they are always willing to think along. We very much appreciate this proactive attitude. As the market leader in the Netherlands, we need a partner who also wants to develop specifically for us and who looks beyond the general market demand. For example, 10% efficiency is logically not that interesting for companies with two work planners. But because we have about thirty work planners, such an efficiency boost does have much effect. And so we have many wishes, which we discuss annually with Matrix Software. In this way, we remain continuously innovative and moving.”

|

|

|

BIM Slim

"What we are currently very busy with, in BIM Slim", says Van der Velde. "We want our customer's Revit models to end up in Matrix OptiCalc automatically. So, we will carry out the process to achieve this together. While we test extensively and share our findings, Matrix Software's software engineers investigate how they can further refine the software. So, we are constantly looking for optimisation."

About Europrovyl

Like Kumij, Transcarbo and Smits Bedrijven Gemert, Europrovyl is part of the VHZ Group. For more than half a century, the company has been a leader in producing, supplying, and assembling plastic facade elements, including complete project management. From frames to doors, windows and sliding doors. “We excel in conceptual new construction, but we are also strong in traditional new construction and renovation projects,” says Van der Velde. “We tackle small and large projects, from one to several hundred homes. With four production locations, approximately 450 skilled employees and a total production of an average of 660 frames per day, we are the market leader in the Netherlands.”

Like Kumij, Transcarbo and Smits Bedrijven Gemert, Europrovyl is part of the VHZ Group. For more than half a century, the company has been a leader in producing, supplying, and assembling plastic facade elements, including complete project management. From frames to doors, windows and sliding doors. “We excel in conceptual new construction, but we are also strong in traditional new construction and renovation projects,” says Van der Velde. “We tackle small and large projects, from one to several hundred homes. With four production locations, approximately 450 skilled employees and a total production of an average of 660 frames per day, we are the market leader in the Netherlands.”

Everything that Europrovyl invents and makes innovation. For example, the Holland Hundred system was developed as early as 1988, with which the Dutch market leader in plastic frames bridged the gap from a flat to a recessed profile system that closely approximates the wooden frame. And the 'Authentic Window' (sliding window frame) comes from Europrovyl. "In 2005, we also introduced the first plastic frame with the so-called wood look connection (HVL/CLK)", explains Technical Director Jan Sytze van der Velde. "Every innovation has been promoted to the Dutch standard and has significantly improved our market position. Extensive robotization and automation also contribute to this, aiming to deliver even higher and more consistent quality and serve customers even better."