CNC for round and arched frames

At Matrix Software in Nijmegen, people never sit still when it comes to innovation. In order to further help the window manufacturer in optimizing production processes, continuous developments are being made that ensure greater efficiency, that save time and money and that contribute to the delivery of high-quality work.

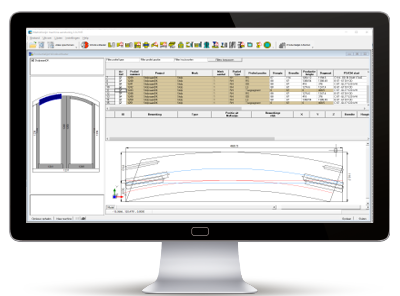

Hans Storms, branch manager for the frame industry, talks about the latest developments:"MatrixKozijn has been supporting the manufacture of round and arched frames for some time now. This was quite a step for the window manufacturer, as making round and arched window frames was very laborious in the pre-production phase until now. A lot of manual measuring and calculation work and manual setting of the machines. We will solve that problem once and for all."

Now also for the Saomad

Due to the complex production process of round and arched frames and the differences that exist between the brands of machines, it is necessary to adapt the software to the respective machine. Storms: "We have been supporting the CNC control for the WindowMaster and the Conturex for some time now. Recently we have also been controlling the Saomad. We have realized this for the first time at Timmerfabriek Salland. The results that are now being achieved are promising."

Straight to the machine

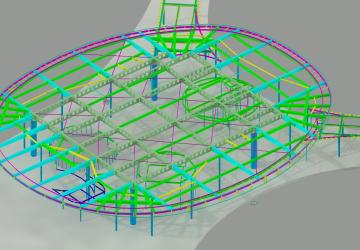

"It is very simple. In MatrixKozijn there is now an option to draw round and arched frames. If the drawing is satisfied, it is sent to MatrixKozijn CNC. The heavy calculations take place there. The software determines the segmentation of the frame. relevant frame and shows a preview of the end product. At that time, adjustments can be made by changing the segmentation, with more or fewer segments. Once that part has been completed satisfactorily, the software determines the run-in for the profiling and the counter molds The final phase is that MatrixKozijn CNC controls the machine."

Removing barriers

The entire production process for round and arched window frames was a barrier for many window companies to get started. A lot of manual and time-consuming work, a lot of testing and then a trial & error process to arrive at a suitable end product. "With our new software everything goes smoothly, easily and quickly. By digitizing the entire process, whereby not only the frame, but also all rotating parts are produced in this way, we hope to remove barriers for the frame manufacturers. the piece of visualization is important. You see exactly what is happening", Storms concludes.

For more information: